- +1-315-215-1633

- sales@thebrainyinsights.com

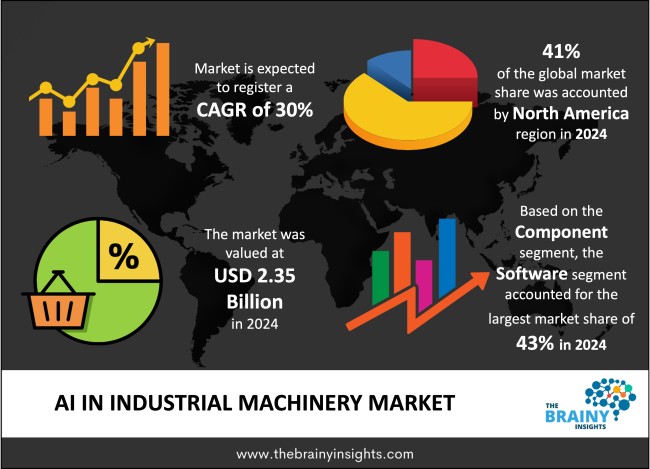

The global AI in industrial machinery market was valued at USD 2.35 billion in 2024 and grew at a CAGR of 30% from 2025 to 2034. The market is expected to reach USD 32.39 billion by 2034. The industry 4.0 revolutions worldwide will drive the growth of the global AI in industrial machinery market.

Artificial intelligence in industrial machinery means the application of highly advanced algorithms, machine learning, and automation technologies into the various manufacturing and other production processes, which are aimed at better efficiency output, better accuracy, and better decision-making. Such AI-enabled industrial machines mainly increase productivity through real-time data analysis, predictive maintenance, quality control, and autonomous operation. Predictive maintenance is one of the most Important of all such applications. Such predictive maintenance allows the machine to analyse sensor data from the machine itself and predict failures even before they happen; hence, it minimizes downtimes and maintenance costs. Another important function is process optimization, in which the ai system manipulates efficiently the machine system's operating parameters in real-time to be maximally efficient and minimization of losses. AI in industry machinery has an integral role to play in computer vision as the high-speed cameras are teamed with deep learning models aimed at automated quality inspection while achieving results beyond human inspector accuracy in defect detection. AI has done wonders in robotics and automation systems since it has enabled machines to quickly adapt and co-ordinate with the ever-changing environment of human operators, perform very demanding tasks, and do all these with minimal or no supervision at all. AI will take over all parts of logistics and supply chain such as forecasting demand, optimizing inventories, and streamlining operations. Furthermore, AI-enabling digital twins can create real-time virtual models of machinery for manufacturers to simulate, analyse, and optimize processes before going into actual implementation, minimizing trial-and-error in production.

Get an overview of this study by requesting a free sample

Through the direct installation of IoT sensors on machinery, Augury helps manufacturing and industrial companies optimise their factory floor maintenance procedures. Real-time measurements are streamed by the sensors' temperature, magnetic field, and ultrasonic vibration detectors.

The expanding industry 4.0 – Industrial machinery applications of AI have become essential because operations need automation and better efficiency. Manufacturers experience consistent pressure to raise their production output through cost-effective systems that reduce instances of errors alongside operational delays. Machines employing artificial intelligence automation produce minimal human-required supervision thereby optimizing manufacturing operations together with higher accuracy levels. The real-time equipment monitoring capability through AI assists businesses to adjust their processes immediately according to changing situations and deliver better throughput while conserving resources. The self-adjusting capabilities of AI-based process optimization allow industrial machinery to make precise parameter changes such as speed and pressure and temperature based on currently collected data. AI integration into industrial machinery receives stronger acceleration from both Industrial IoT (IIoT) and smart factories operations. The integration of AI in factories enables the creation of connected systems where devices network to forecast breakdowns while simultaneously optimizing their manufacturing processes.

High costs of AI in industrial machinery – The unwillingness of industries to use AI for industrial machinery stems from expensive deployment costs and unpredictable return on investment (ROI). Using artificial intelligence solutions demands businesses to pay considerable initial costs for hardware as well as software platforms and infrastructure and skilled workforce. The implementation of AI-powered smart robotics and predictive maintenance systems with process automation requires high-performance computing systems that use IoT sensors to connect real-time processing units thus increasing the overall cost. Small and medium-sized enterprises (SMEs) struggle to adopt AI because large corporations possess financial capabilities for AI investments yet the ROI from AI remains unclear to SMEs thus justifying the high costs becomes challenging. Many organizations face difficulties obtaining short-term financial confirmation of AI solutions because its performance advantages including enhanced operational efficiency and downtime reduction and better-quality management become evident only through sustained use.

Advancements in AI and other novel technologies – The developments of artificial intelligence together with machine learning technologies deliver improved operational abilities to industrial equipment. The continuous improvements in deep learning and natural language processing (NLP) and reinforcement learning enable AI systems to process large amounts of industrial data and make advanced predictive failure assessments and superior decision optimization possibilities. Computers equipped with AI vision modules can now identify small product issues for optimal quality management capabilities. AI solutions have become more accessible and cost-efficient because of recent technological developments thus industries embrace them willingly. The growth of smart production together with digital cloning serves as a main reason for the rise in AI adoption. The market continues growing because governments actively back the implementation of AI technology for industrial needs through funding and policy support. Various national programs and incentives as well as AI-friendly administrative policies exist to support AI research throughout the world.

The regions analyzed for the market include North America, Europe, South America, Asia Pacific, the Middle East, and Africa. North America emerged as the most significant global AI in industrial machinery market, with a 41% market revenue share in 2024.

The United States and Canada stand at the forefront of AI adoption because their industrial sector is experienced and their manufacturing abilities are advanced while research and development activities promote AI-driven automation. North America leads in industrial technology adoption because it has evolved with the Fourth Industrial Revolution through use of AI robots and IoT devices. Industrial machinery gets faster integration given the presence of major AI technology providers such as IBM, Google, Microsoft and NVIDIA. High costs of labour together with rising automation demands cause industries to embrace AI-powered robotics systems and smart solutions for manufacturing applications. additionally, the U.S. government together with private sector entities have invested resources into AI-based research along with smart factory development and digital infrastructure creation which has established the region as the forefront of automated industrial practices.

North America Region AI in Industrial Machinery Market Share in 2024 - 41%

www.thebrainyinsights.com

Check the geographical analysis of this market by requesting a free sample

The component segment is divided into hardware, software and services. The software segment dominated the market, with a market share of around 43% in 2024. Software executes essential functions such as intelligent automation, predictive analytics and real-time decision-making abilities. Business operations that use AI power their core functions through machine learning algorithms and deep learning frameworks. Software solutions provide scalable features with flexible use and affordable pricing unlike hardware needs. Advancements of both cloud-based AI platforms and edge computing solutions drive the growth of software segment. AI software serves as an essential instrument in quality inspection systems. Industrial software establishes IoT connectivity which enables data collection and processing and interpretation of machine data to optimize operational procedures. The market demand for AI software continues to rise because of ongoing developments in AI algorithms together with automation tools and industrial AI-as-a-service models which will lead AI software to become the main element within the market of AI-driven industrial machinery.

The technology segment is divided machine learning & deep learning, computer vision, natural language processing (NLP) and context-aware computing. The machine learning & deep learning segment dominated the market, with a market share of around 39% in 2024. The dominance of ML and DL comes mainly from their ability to perform predictive maintenance along with process optimization tasks. Operational data continuously undergoes ML model analysis to identify machinery defects in their developing state thus enabling industries to deliver proactive maintenance solutions instead of emergency repairs. The utilization of this technology enables equipment maintenance before failures happen which leads to longer operational life alongside increased productivity. The industrial machinery market now depends on ML and DL technologies because Industrial IoT (IIoT) and digital twins and AI-driven robotics have been gaining widespread adoption.

The application segment is divided into predictive maintenance & machine health monitoring, process optimization & control, quality inspection & defect detection, supply chain & inventory management and human-machine collaboration (Cobots). The predictive maintenance & machine health monitoring segment dominated the market, with a market share of around 24% in 2024. The primary reason why predictive maintenance dominates the market stems from its ability to decrease operational costs together with its benefits to productivity levels. Predictive maintenance delivers maximum benefits for industries with substantial capital expenses in machinery including automotive and aerospace sectors together with energy and manufacturing operations. The combination of cloud-based AI solutions with edge computing technologies lets organizations perform real-time monitoring through automated decision-making systems along with remote diagnostics capabilities. Predictive maintenance has become a fundamental application in smart manufacturing under Industry 4.0 conditions because it achieves greater operational efficiency along with reduced operational risks and long-term cost savings through digital twins and AI automation. AI application in industrial machinery functions through prevention and optimization of processes which has earned it its position as the most popular use of AI in industrial machinery.

The end-user segment is divided into manufacturing & automotive, energy & utilities, aerospace & defence, food & beverage and healthcare & pharmaceuticals. The manufacturing & automotive segment dominated the market, with a share of around 35% in 2024. The manufacturing sector together with the automotive industry leads the AI-driven industrial machinery market because they fast-tracked their adoption of automation, robotics and smart manufacturing technologies. These industries require AI solutions to enhance their efficiency and precision and scale up operations since they need AI-driven solutions to remain competitive at a global level. The manufacturing industry widely implements AI to conduct predictive maintenance operations and automate processes as well as inspect quality and optimize its supply chains. The automotive manufacturing industry depends on artificial intelligence for vehicle assembly operations together with self-determining vehicles and control of supply chain systems. The manufacturing sector and automotive industry maintain their position as top segment drivers in AI-powered industrial machinery through implementations from Industry 4.0 coupled with smart manufacturing methods and automated systems.

| Attribute | Description |

|---|---|

| Market Size | Revenue (USD Billion) |

| Market size value in 2024 | USD 2.35 Billion |

| Market size value in 2034 | USD 32.39 Billion |

| CAGR (2025 to 2034) | 30% |

| Historical data | 2021-2023 |

| Base Year | 2024 |

| Forecast | 2025-2034 |

| Region | The regions analyzed for the market are Asia Pacific, Europe, South America, North America, and Middle East and Africa. Furthermore, the regions are further analyzed at the country level. |

| Segments | Component, Technology, Application and Industry Vertical |

As per The Brainy Insights, the size of the global AI in industrial machinery market was valued at USD 2.35 billion in 2024 to USD 32.39 billion by 2034.

Global AI in industrial machinery market is growing at a CAGR of 30% during the forecast period 2025-2034.

The market's growth will be influenced by the expanding industry 4.0.

High costs of AI in industrial machinery could hamper the market growth.

This study forecasts revenue at global, regional, and country levels from 2021 to 2034. The Brainy Insights has segmented the global AI in industrial machinery market based on below mentioned segments:

Global AI in Industrial Machinery Market by Component:

Global AI in Industrial Machinery Market by Technology:

Global AI in Industrial Machinery Market by Application:

Global AI in Industrial Machinery Market by Industry Vertical:

Global AI in Industrial Machinery Market by Region:

Research has its special purpose to undertake marketing efficiently. In this competitive scenario, businesses need information across all industry verticals; the information about customer wants, market demand, competition, industry trends, distribution channels etc. This information needs to be updated regularly because businesses operate in a dynamic environment. Our organization, The Brainy Insights incorporates scientific and systematic research procedures in order to get proper market insights and industry analysis for overall business success. The analysis consists of studying the market from a miniscule level wherein we implement statistical tools which helps us in examining the data with accuracy and precision.

Our research reports feature both; quantitative and qualitative aspects for any market. Qualitative information for any market research process are fundamental because they reveal the customer needs and wants, usage and consumption for any product/service related to a specific industry. This in turn aids the marketers/investors in knowing certain perceptions of the customers. Qualitative research can enlighten about the different product concepts and designs along with unique service offering that in turn, helps define marketing problems and generate opportunities. On the other hand, quantitative research engages with the data collection process through interviews, e-mail interactions, surveys and pilot studies. Quantitative aspects for the market research are useful to validate the hypotheses generated during qualitative research method, explore empirical patterns in the data with the help of statistical tools, and finally make the market estimations.

The Brainy Insights offers comprehensive research and analysis, based on a wide assortment of factual insights gained through interviews with CXOs and global experts and secondary data from reliable sources. Our analysts and industry specialist assume vital roles in building up statistical tools and analysis models, which are used to analyse the data and arrive at accurate insights with exceedingly informative research discoveries. The data provided by our organization have proven precious to a diverse range of companies, facilitating them to address issues such as determining which products/services are the most appealing, whether or not customers use the product in the manner anticipated, the purchasing intentions of the market and many others.

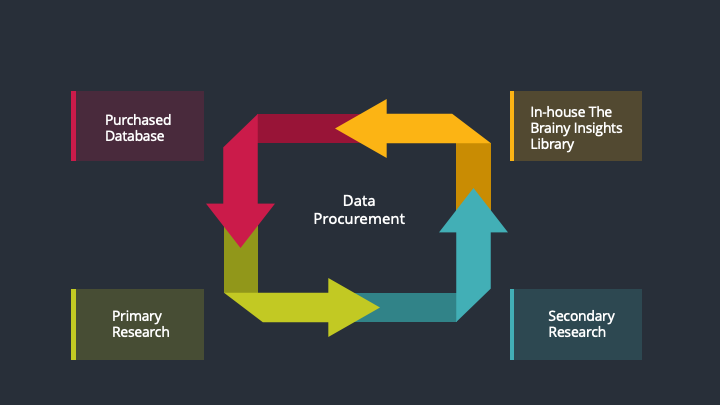

Our research methodology encompasses an idyllic combination of primary and secondary initiatives. Key phases involved in this process are listed below:

The phase involves the gathering and collecting of market data and its related information with the help of different sources & research procedures.

The data procurement stage involves in data gathering and collecting through various data sources.

This stage involves in extensive research. These data sources includes:

Purchased Database: Purchased databases play a crucial role in estimating the market sizes irrespective of the domain. Our purchased database includes:

Primary Research: The Brainy Insights interacts with leading companies and experts of the concerned domain to develop the analyst team’s market understanding and expertise. It improves and substantiates every single data presented in the market reports. Primary research mainly involves in telephonic interviews, E-mail interactions and face-to-face interviews with the raw material providers, manufacturers/producers, distributors, & independent consultants. The interviews that we conduct provides valuable data on market size and industry growth trends prevailing in the market. Our organization also conducts surveys with the various industry experts in order to gain overall insights of the industry/market. For instance, in healthcare industry we conduct surveys with the pharmacists, doctors, surgeons and nurses in order to gain insights and key information of a medical product/device/equipment which the customers are going to usage. Surveys are conducted in the form of questionnaire designed by our own analyst team. Surveys plays an important role in primary research because surveys helps us to identify the key target audiences of the market. Additionally, surveys helps to identify the key target audience engaged with the market. Our survey team conducts the survey by targeting the key audience, thus gaining insights from them. Based on the perspectives of the customers, this information is utilized to formulate market strategies. Moreover, market surveys helps us to understand the current competitive situation of the industry. To be precise, our survey process typically involve with the 360 analysis of the market. This analytical process begins by identifying the prospective customers for a product or service related to the market/industry to obtain data on how a product/service could fit into customers’ lives.

Secondary Research: The secondary data sources includes information published by the on-profit organizations such as World bank, WHO, company fillings, investor presentations, annual reports, national government documents, statistical databases, blogs, articles, white papers and others. From the annual report, we analyse a company’s revenue to understand the key segment and market share of that organization in a particular region. We analyse the company websites and adopt the product mapping technique which is important for deriving the segment revenue. In the product mapping method, we select and categorize the products offered by the companies catering to domain specific market, deduce the product revenue for each of the companies so as to get overall estimation of the market size. We also source data and analyses trends based on information received from supply side and demand side intermediaries in the value chain. The supply side denotes the data gathered from supplier, distributor, wholesaler and the demand side illustrates the data gathered from the end customers for respective market domain.

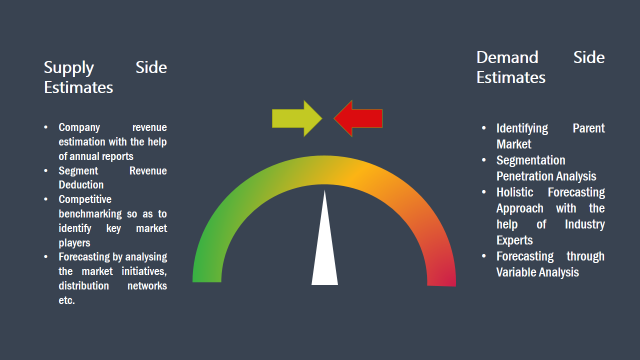

The supply side for a domain specific market is analysed by:

The demand side for the market is estimated through:

In-house Library: Apart from these third-party sources, we have our in-house library of qualitative and quantitative information. Our in-house database includes market data for various industry and domains. These data are updated on regular basis as per the changing market scenario. Our library includes, historic databases, internal audit reports and archives.

Sometimes there are instances where there is no metadata or raw data available for any domain specific market. For those cases, we use our expertise to forecast and estimate the market size in order to generate comprehensive data sets. Our analyst team adopt a robust research technique in order to produce the estimates:

Data Synthesis: This stage involves the analysis & mapping of all the information obtained from the previous step. It also involves in scrutinizing the data for any discrepancy observed while data gathering related to the market. The data is collected with consideration to the heterogeneity of sources. Robust scientific techniques are in place for synthesizing disparate data sets and provide the essential contextual information that can orient market strategies. The Brainy Insights has extensive experience in data synthesis where the data passes through various stages:

Market Deduction & Formulation: The final stage comprises of assigning data points at appropriate market spaces so as to deduce feasible conclusions. Analyst perspective & subject matter expert based holistic form of market sizing coupled with industry analysis also plays a crucial role in this stage.

This stage involves in finalization of the market size and numbers that we have collected from data integration step. With data interpolation, it is made sure that there is no gap in the market data. Successful trend analysis is done by our analysts using extrapolation techniques, which provide the best possible forecasts for the market.

Data Validation & Market Feedback: Validation is the most important step in the process. Validation & re-validation via an intricately designed process helps us finalize data-points to be used for final calculations.

The Brainy Insights interacts with leading companies and experts of the concerned domain to develop the analyst team’s market understanding and expertise. It improves and substantiates every single data presented in the market reports. The data validation interview and discussion panels are typically composed of the most experienced industry members. The participants include, however, are not limited to:

Moreover, we always validate our data and findings through primary respondents from all the major regions we are working on.

Free Customization

Fortune 500 Clients

Free Yearly Update On Purchase Of Multi/Corporate License

Companies Served Till Date